Elbow Shield 45/90/180 Repair System

Repair Clamp for 45/90/180 Elbow Fittings,

Inner and Outer Radius, up to 1200psi max.

True or False?

» Less unplanned shutdowns and repair expenses lead to increased company profits?

» Shutting down well operations for 7 days to repair leaks in elbows can result in a 2% loss in annual production?

(365 days/ 7 days repairs = 1.9% of annual production time)

» It costs less to plan ahead for a potential leak than it is to clean up after oil spills into the environment?

Kern River, Bakersfield. 8inch Elbow Shield installed as a proactive measure after a high-risk/ thin wall UT reading

Innovative Maintenance Products has developed a new pipeline maintenance tool, the Elbow Shield 45/90/180 Repair System, to stop leaks in 45 & 90 elbows and 180 return fittings. An elbow bend is the most turbulent section of a pipeline as redirecting the flow of fluid and solid particles cause internal erosion to occur. At some point in time, the pipe wall will become too thin and a pinhole leak will develop from the inside out. Beginning with a few drops, then becoming a larger flowing leak as the fluid which is under pressure finds a new unrestricted outlet.

- A common straight pipe clamp will not fit the compound curves of an elbow fitting making these types of leaks previously uncontainable.

Engineered to perform oilfield tough.

The Elbow Shield Repair System uses a unique two gasket design, with an inner and outer seal, to offer the flexibility of stopping leaks anywhere along the elbow fixture surface, even near a weld edge. A single user can immediately contain an elbow leak while the pipeline is still in production, without any modification to the existing elbow fixture or pipeline. The HNBR gaskets have a specially designed grid pattern with fluid chambers for a tighter seal and allow for slight variances in pipe diameter due to manufacture of origin. The brackets are engineered with a bolt locking mechanism that allows for rapid application and is built with heavy gauge metal and hardware to ensure a strong sealing force in order to stop leaks completely.

Elbow Shields in 2″, 3″, 4″, 6″ and 8″ *** Patent Pending and Patents Issued

Specifications:

- Available in nominal pipe sizes of 1/2” up to 24” for complete pipeline leak preparedness

- LDP Shields are available for large diameter pipelines of 26″ to 48″, contact us for more information

- HNBR gaskets have a temperature rating of -20 to +325F max. and H2S resistance up to 4% Max. (40,000PPM)

- Fits long radius 45(LR) and 90(LR) elbows and 180(LR) returns most commonly used in industrial pipelines

- NOTE: May also fit short radius 90(SR) elbows, 45(3R), and 90(3R) elbows and machine/ hand bent pipes depending on the leak hole placement. Each case must be evaluated by the installer for proper sealing fitment.

- PSI rating can be up to 1300psi max depending on the size of the tool, contact us for detailed specs

Features:

- Uses standard size bolts and nuts with a quick-latch design for quick and easy installation

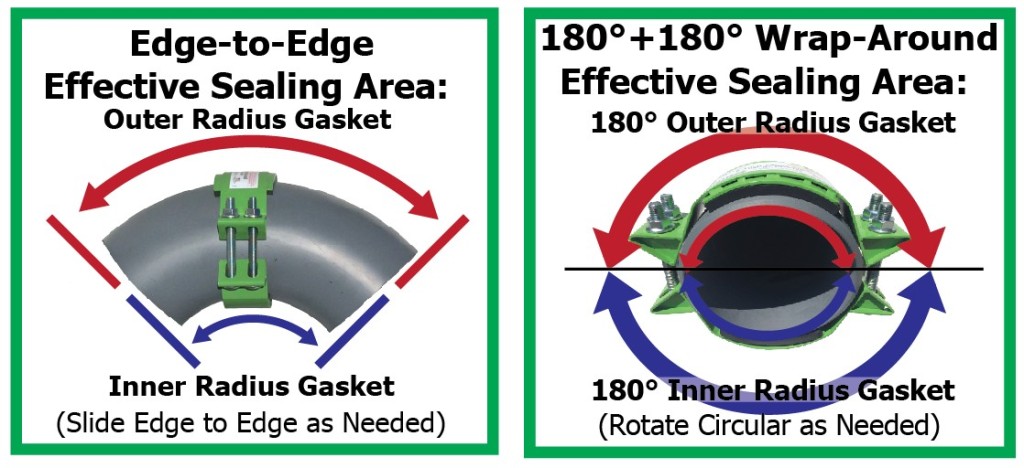

- Unique double-gasket design provides edge to edge sealing effectiveness along the outer and inner radius of the elbow and return fittings

- Engineered for 360° circular wrap-around sealing effectiveness for complete protection

- Gaskets have a special grid pattern with fluid chambers to ensure a tight seal

- Utilizes HNBR (Hydrogenated Nitrile) gaskets for superior resistance; crude oil, refined products, water, steam, and gas

Benefits:

- In less than 2 minutes a single person is able to immediately stop pipeline leaks using standard tools

- Prevent environmental contamination by stopping leaks as soon as they are detected

- Avoid unplanned shutdowns and maintain operations until you are able to schedule the necessary repairs

- Control repair expenses by continuing to utilize the existing pipeline fittings

- Use as a precautionary measure to prevent leaks from occurring after a high-risk/thin wall UT reading

Industries served by the Elbow Shield line of products:

Chemical & Petrochemical Plants • Water & Wastewater Treatment Facilities • Transportation & Infrastructure

Power-Gen Facilities • Pulp & Paper Mills • Food, Dairy & Beverage • Pharmaceutical • Marine & Coastal Facilities

Offshore Platforms • Cooling Towers • Fertilizer Plants • Breweries • Mining

A “composite pipe wrap” is NOT a pinhole leak option!

Prior to the Elbow Shield, there was no temporary repair option on the market which could stop leaks on elbow fittings to keep production flowing. The only option was to shut down wells and flow lines completely for 4 to 7 days until the replacement pipe could be “spec’d” out, materials ordered and repairs completed by large work crews. Being prepared to immediately stop elbow leaks can help save thousands of dollars in lost production from downtime and reduce the risk of environmental damage and costly clean-up due to oil spills. Now oil producers, midstream transporters, and service companies can install the Elbow Shield within minutes of a leak detection at a substantially lower cost per leak incident expense.

Code of Federal Regulation, CFR Part 195.422, Enforcement Guidance O&M Part 195, Section “Pipeline Repairs”, (9) – pg. 94, Composite pipe wraps, “…cannot be used on defects that go through the pipe walls.”

Code of Federal Regulations, CFR 40 Part 112, “SPCC Planning”

Did you know that CFR 40 Part 112 requires a Spill Prevention Control and Countermeasure (SPCC) plan to include a description of a facility’s response equipment to stop gathering and flowline discharges in a timely manner (5 minutes or less). The Elbow Shields should be part of every emergency response plan to stop leaks immediately.