Valve Speed Handle

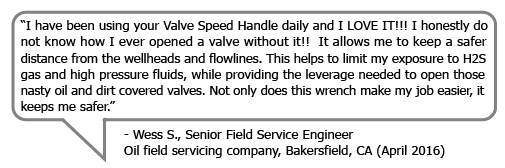

Safety Tool for Valve Operations

True or False?

» Less worker injury related expenses lead to increased company profits?

» To keep production levels up with a reduced workforce, individual productivity needs to increase?

In a joint effort with Chevron’s San Joaquin Valley Business Unit, Innovative Maintenance Products has developed a new maintenance safety tool, the Valve Speed Handle, to make valve operations safer, easier and faster. Chevron asked to have a tool developed for field operators performing valve operations to reduce the risk of injuries and improve productivity. The design elements were based on Chevron’s requirements from the HES group, a Certified Ergonomist, and the field operators that would be using the tool daily. After the successful completion of field testing by 20 field operators over 6-months, it was approved for full deployment. Today, 100’s of Valve Speed Handles are in use by Chevron and other oil and gas companies with great success in user adoption and operator satisfaction.

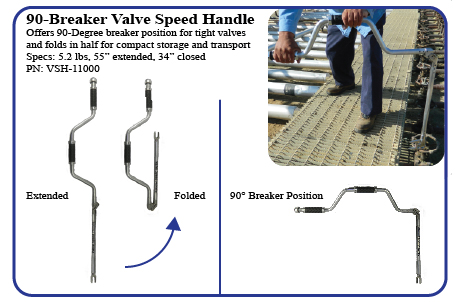

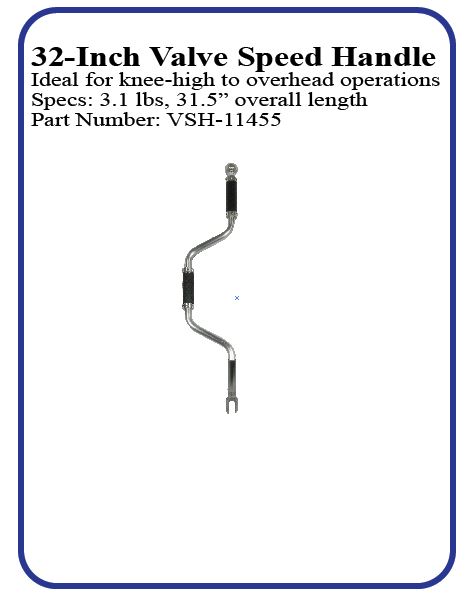

3 Design Styles to Choose From

** Patent Pending, Other Patents Issued

Which are the highest risk oil field job tasks?

Valve operations, the opening, and closing of flow valves are commonplace at any oil and gas operation as these fixtures allow for pipelines to flow and stop as needed. The operators who perform these valve operations on a daily basis can be part of the highest risk group because of the high fluid pressure, hot fluid temperatures, hazardous chemicals they contain, and the condition of each valve can be unknown making it a possibility something can go wrong at any time. In addition, valve operations can be necessary for a variety of reasons throughout any given oil field, big or small, day or night, and every day of the year.

What is one of the higher risk dangers that can occur?

Valve packing blowouts can occur when a flow valve is opened after the packing seal has deteriorated over time due to internal and external conditions such as high heat or other conditions. Typically, an operator has to place both on the valve to be opened putting his face and body directly over the valve fixture, and rotate the valve wheel until it reaches the open position. At any time the high fluid pressure can cause the packing material to explode outward and upward into the operator’s face and body, along with any release of the fluid inside, possibly causing serious bodily injury. This is just one example of many dangers that can occur while servicing flow valves.

Who are the highest risk operators?

Any operator who works in the field and performs the task of opening or closing flow valves once a month or on a daily basis is considered “at-risk”. During our evaluation at Chevron’s Kern River oil field, the highest risk operators were identified as being the cyclic steam group of operators. They are considered the highest risk due to the high repetition of valve operation tasks they perform over their 12-hour shifts, often opening and closing over 100 valves each shift. These operators are as tough a group as there is, but towards the end of a long shift, an operator could be performing job functions while fatigued. In most oil fields the older systems and wellheads were not designed with a worker in mind which may put an operator in an awkward posture to perform their job tasks. In addition, some valves can require a greater amount of force to be opened which can be difficult while reaching down to ground level.

Satisfy the H.E.S. Group, Certified Ergonomist, and Field Operators all at the same time?

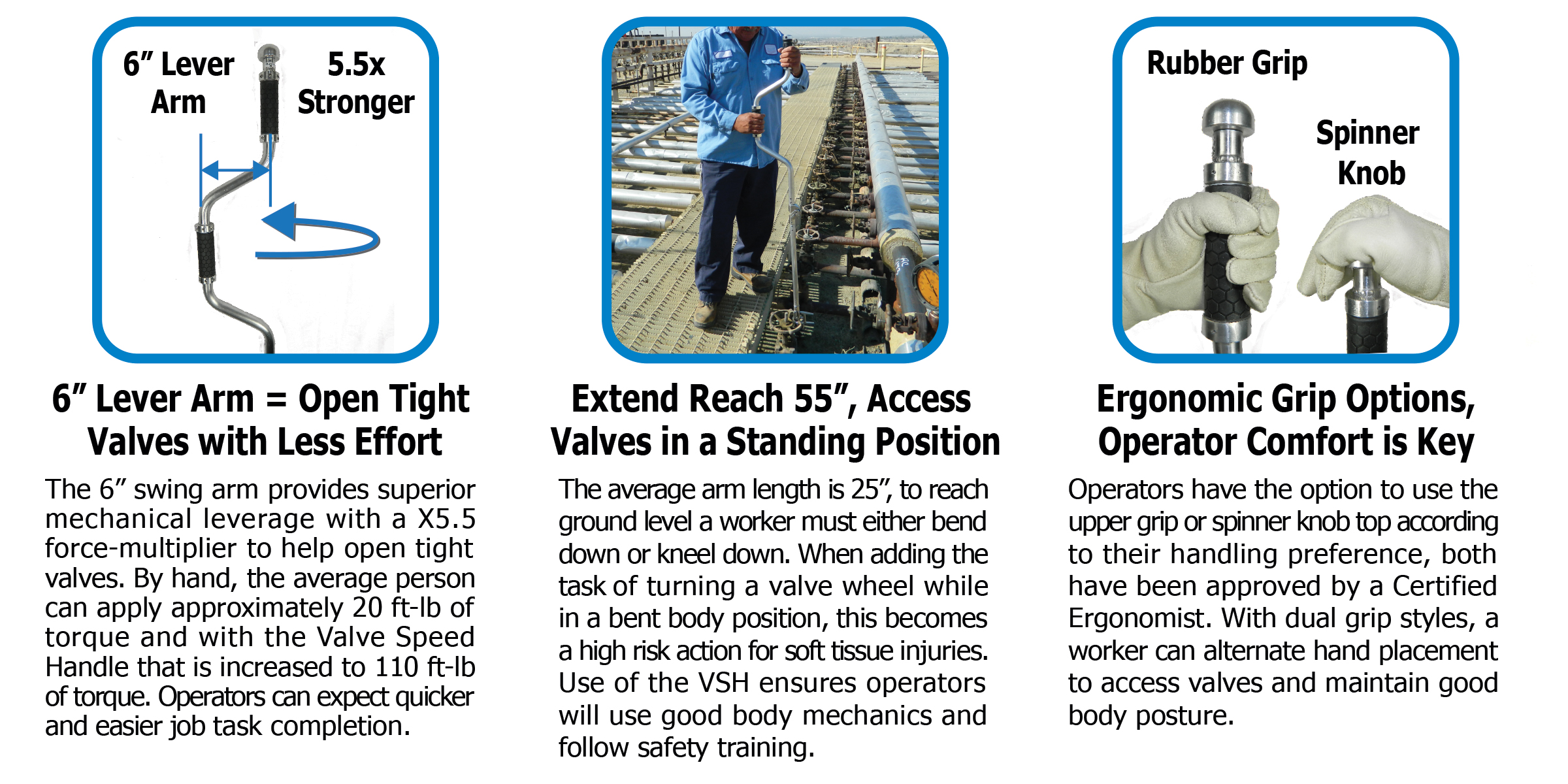

In working with several of Chevron’s top teams, the requirements were clear; be lightweight, provide sufficient leverage to open tight valves, and meet the ergonomics needs for average user height and hand size. For the operators, there were a few items on their wish list too such as incorporating a spinner top handle for quicker turning of valve wheels, ensuring the forkhead could fit a larger variety of valve wheel sizes and is deep enough to use at all angles of access. There were field safety requirements such as being spark and corrosion-resistant, plus having very little maintenance needs for long field use in rough conditions. The Valve Speed Handle had to be designed and engineered to meet the toughest requirements in oil and gas operations.

Built Oil Field Tough.

After a strong team effort, IMP delivered in a big way. Once the new Valve Speed Handles were delivered, the operators were very impressed and eager to get them into the field for use. The Valve Speed Handle weighs just 3.6 pounds which is well below Chevron’s H.E.S and Certified Ergonomist expectations. Being lightweight allows operators to maintain good body posture and decrease stress on the shoulder and neck areas during use. Our engineers reached the optimal balance of lever arm positioning and good body mechanics to provide the highest rotating leverage possible. The rubber handgrips and spinner knob top are manufactured to fit the exact ergonomic specifications, which is great for operators while using safety gloves.

Reduce the Risk in These Common Situations:

» Minimize risk of muscle strain while in a bent position

» Remove a worker’s face and body from the packing blowout danger zone

» Eliminate entry into active wellhead gated areas for valve access

» Avoid entering cellars and H2S dangers on well platforms

Key Tool Features:

» 6-inch lever arm provides user 5.5x stronger turning force compared to turning valves by hand

» Multiple handles allow for the user to choose best grip option for good body posture

» Built with a heavy-duty, lightweight aluminum frame for less muscle fatigue throughout the workday

» Uses a stainless steel fork and hardware for spark and corrosion resistance

» Certified Ergonomist approved rubber grips and spinner knob for working while wearing gloves

» Max Torque Rating of 110 ft-lb

» Limited 12-month warranty