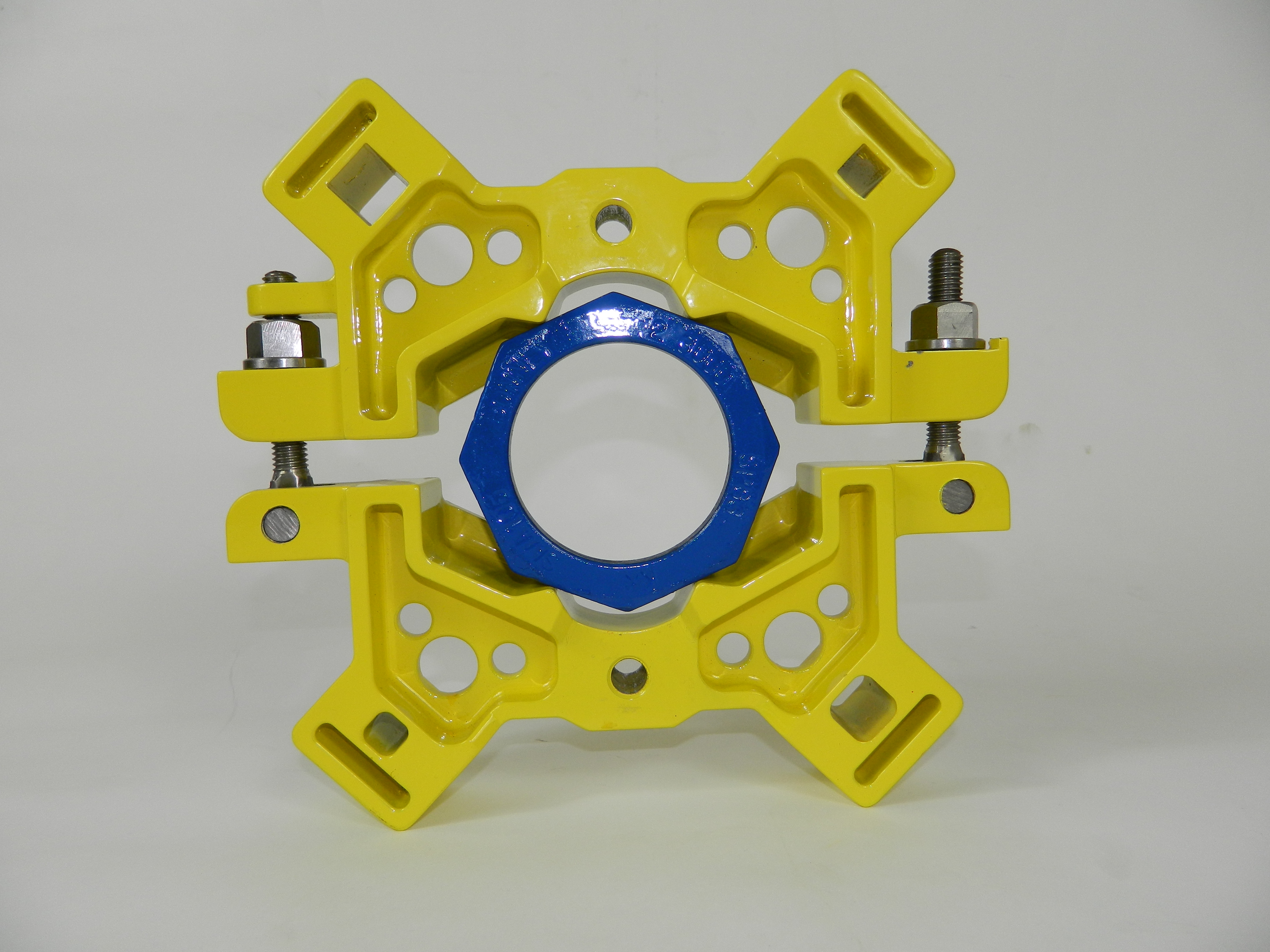

Nut & Pipe Adapter

Use a Hammer to Install and Breakdown Nut Unions

Instead of a 36” or 48” Pipe Wrench

► Use a hammer on pipe fittings instead of a 36” or 48” pipe wrench

► Make-up and break-down Nut Unions similar to a Hammer Union

► Can be used on pipe nipples, pipe coupling and other threaded fittings

Energy producers that operate legacy oil fields often decide not to spend the money to go back and replace the

nut unions in their pipelines with hammer unions as the costs can reach upwards of $1000’s in parts and labor

for each union. We partnered with a large global oil producer, which operates dozens of legacy oil fields dating back to the 1900’s, to develop a solution which provides workers an easier way to make up and break down the existing nut unions using the impact force of a hammer.

The major challenge was that union nuts come in many different sizes and shapes depending on the nominal pipe

size and manufacturing company’s design. The Nut Adapter is engineered to be universal to fit 6 and 8-sided nuts

in all sizes found in the oil field today. In addition, we developed an attachment with gripper teeth to fit on union male and female subs/ends, pipe nipples, pipe couplings and other round threaded fittings which may also be required to be removed as part of the union maintenance services process.

To use the Nut Adapter, a person simply spreads the Nut Adapter brackets apart, swing the brackets over the nut

and closes into place. It can be easily mounted on horizontal and vertical position union nuts and fittings. Once the Nut adapter is in position, swing the locking bolt into place and tighten down both nuts evenly until it is securely fastened. The worker can now use a hammer to impact any of the six (6) impact zones to rotate the union nut.

KEY BENEFITS:

- Gain the benefits of using hammer force without having to replace your currently installed nut unions

- Make up and break down nut unions and other fittings quicker, easier, and safer than using pipe wrenches

- Use in tight spaces where a 36” and 48” pipe wrench might not fit or be easy to use

- 1/2” and 3/4” drive receiver allow for use of common hands tools for medium turning force

- Reduce the risk of worker injury from yanking and tugging on the end of a pipe wrench

- Get a stronger, leak-free seal in nut unions even when the pipes are not aligned perfectly

KEY FEATURES:

- Universal design can fit 6 and 8-sided nuts, 4” to 5.25” point to point measurement (3.75” to 5” side to side)

- Six (6) impact zones around the tool for continuous rotation during use

- Compact design allows for use where space is limited, where 36“ and 48” pipe wrenches cannot fit

- Retainer clips help hold tool in place while using on vertical installations

- ½” and ¾“ drive receivers allow workers to use a breaker bar for light to medium turning force

- Available Pipe Attachment installs to fit 2”OD to 3-1/2”OD union male/female ends, nipples and couplings

- Light weight at 14.4 lbs (6.5kg)